The Van der Graaf SSV drum motors bringing sanitary solutions to new heights

The new all 316 stainless steel drum motor with an IP 69k enclosure can withstand 3,000 psi wash down pressure.

In food processing plants, implementing sanitation processes to battle bacteria has increasingly become more challenging. Equipment manufacturers are required to design food-processing machinery that minimizes crevices where bacterial can harbor. Belt conveyors transferring food products to a number of processing stations has become ground zero for bacteria deposits. For this reason, belt conveyors are required to undergo frequent wash-down cycles. The wash-down process is usually done by pressure washing belt conveyors with warm water mixed with cleansing chemicals in order to remove, kill, or neutralize harmful bacteria.

Although shocking a conveyor with high pressure water doesn’t create a problem for the belt or the conveyor frame, it is a huge problem for the electric motor of the conveyor drive. Traditionally, to avoid electric motor failures, food processing conveyor manufacturers have opted to use hydraulic motors to power the belts. Although hydraulic motors are not sensitive to the washdown process, the concept has two main disadvantages. One, if the plant needs to increase production it could eventually exceed the hydraulic system capacity. The other disadvantage is the possibility of a hydraulic line burst. If this occurs, hydraulic fluid would spray and contaminate the food products in a large area, resulting in significant amount of product disposal.

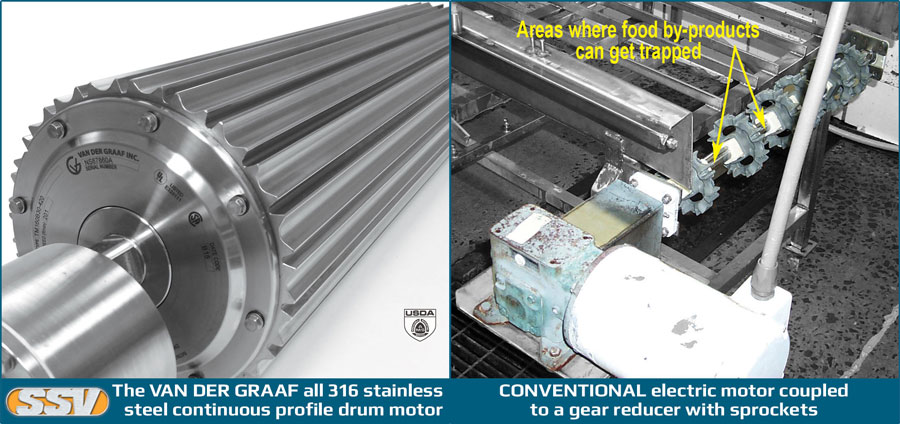

Using an electric motor coupled to a gear reducer has become a common practice of driving a conveyor belt. As previously noted, however, the washdown process will negatively impact the reliability of the electric motor. The Van Der Graaf drum motor by design addresses sanitation and reliability.

The Van Der Graaf SSV sanitary drum motor houses all vital components like the motor, bearings and gear reducer within the drive drum. All components operate in a food grade oil bath for proper lubrication, as well as, heat dissipation. There are no external moving components like shafts or pillow block bearings that requires maintenance.

The Van Der Graaf sanitary drum motor features all 316 stainless steel construction and IP69K enclosure, which can withstand wash-down pressure up to 3,000 psi. No scheduled maintenance is required. Only a simple oil change every 50,000 hours of operation is recommended. Although the Van Der Graaf drum motor is most commonly used to drive flat belts, it is also offered with special profiles to accommodate stainless steel or nylon sprockets to drive extruded and modular style belts of different manufacturers, such as Intralox (Thermodrive), Volta (SuperDrive) amongst others.

The latest Van der Graaf design features an all stainless steel profile, which is used to drive extruded or modular belts without the need of sprockets. A conveyor belt driven by sprockets takes more time to clean, as food byproducts get trapped in the areas between the sprockets, which increase the potential for bacterial contamination. The Van der Graaf all stainless steel continuous profile drum motor design has contributed to the unprecedented popularity of the SSV sanitary drum motor in the food processing industry.

View original article