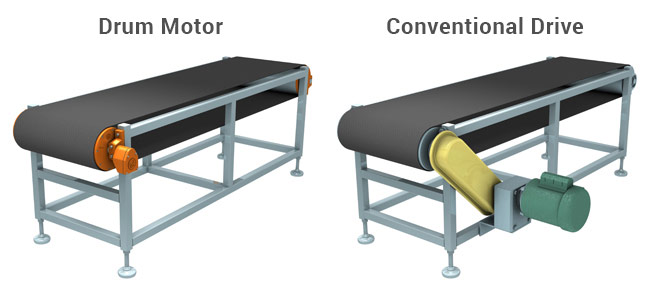

A belt conveyor consists of a structural frame, idler, head roller, and a belt. The head roller is supported on the conveyor frame by pillow block bearings that are maintenance intensive and require frequent lubrication. The belt is traditionally driven by the head roller, that is mechanically connected to an external motor and gearbox (conveyor drive). The electric motor and gear box is mounted on a platform adjacent to the conveyor frame. The external components of a traditional conveyor drive, including the electric motor and gearbox, pose hazards to worker safety and require routine maintenance.

The VDG Drum Motor does not have an external motor or gearbox. The drum motor is mounted on the conveyor frame with non-rotating square shafts extending on both ends of the drum using brackets. The VDG Drum Motor does not have any external rotating components requiring maintenance, which is an important design departure from traditional conveyor drives requiring frequent and costly maintenance to keep the system running. All drum motor drive components, including the electric motor, gear reducer and bearings are enclosed and protected inside the drum, increasing workforce safety. With the electric motor inside the drum coupled in-line to the gear reducer, the VDG Drum Motor has 96% mechanical efficiency and 25% higher electrical efficiency compared to a traditional conveyor drive with an external motor mounted at 90° to the gearbox.

Configure your drive