Evolving Conveying Technology Prioritizes Food Safety and Durability

Like other processes in meat packing, processor concerns involving the motors that run their conveyors tend to revolve around efficiency, reliability, longevity, sanitation, and how it stands up to washdown cycles during the sanitization routine.

"Maintenance and operational costs are also a major concern now with more pressure on processors to reduce operational costs and increase uptime," said Alex Kanaris, president of Van der Graaf Corp., Shelby Township, Mich.

Conveyor motors have gone through a few changes over the years. Permanent magnet motors, high-efficiency motors and the elimination of motor housings have all become go-to variations.

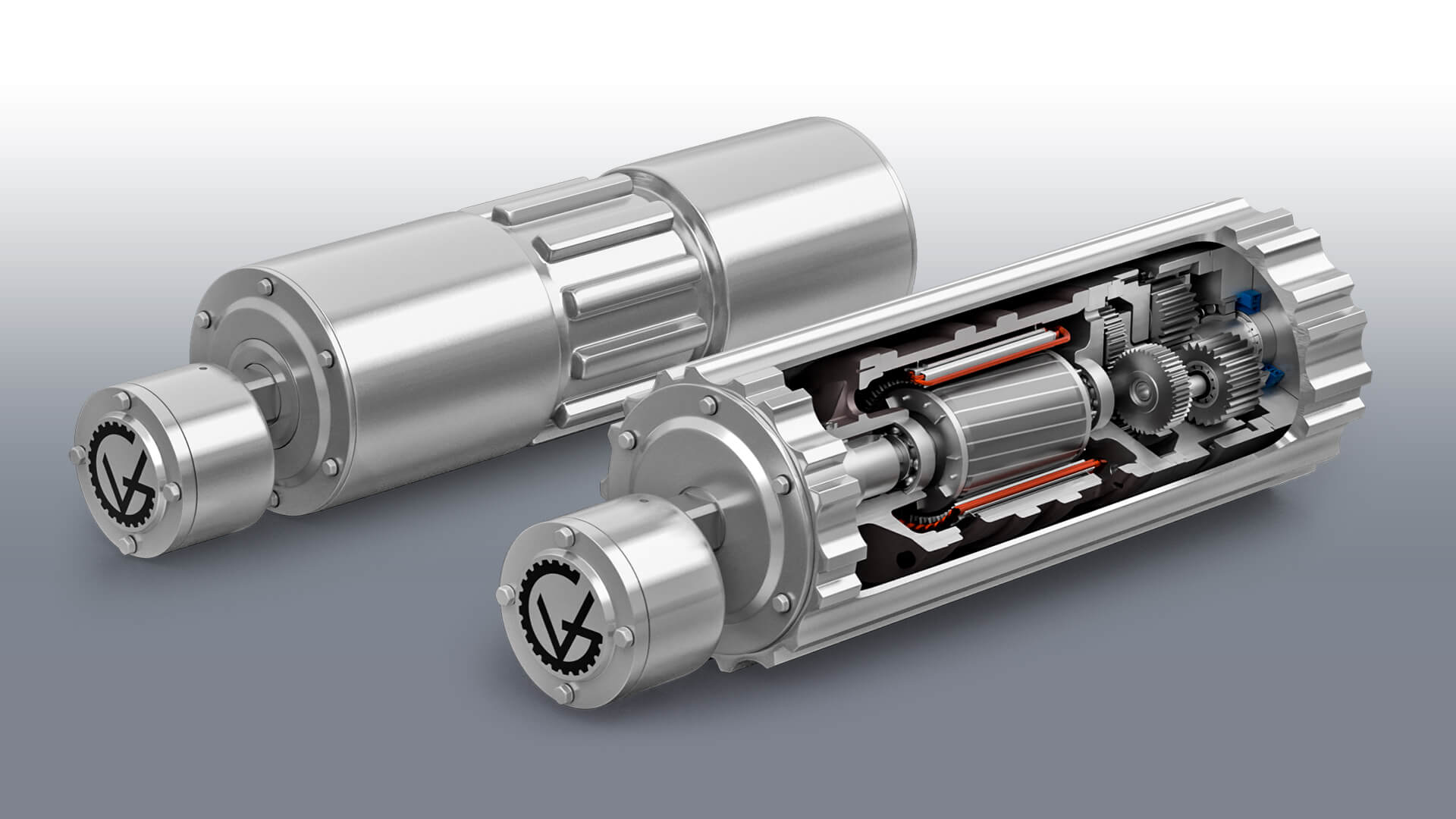

Drum style motors offer hygienic and efficiency advantages. The SSV Series Drum Motor from Van der Graaf has the belt profile machined directly onto a stainless steel drum where all drive components are enclosed and protected inside the drum. It drives modular conveyor belts without using sprockets, eliminating gaps, crevices, and bacterial harborage areas.

Drive motor companies and conveyor belt companies do collaborate to ensure their customers get the best solution to their conveyor needs. The collaboration allows for good combinations that serve the industry, as well as the individual processor.

View original article