Exchangeable Continuous Profile Drum Motor Sleeves Provide Flexibility

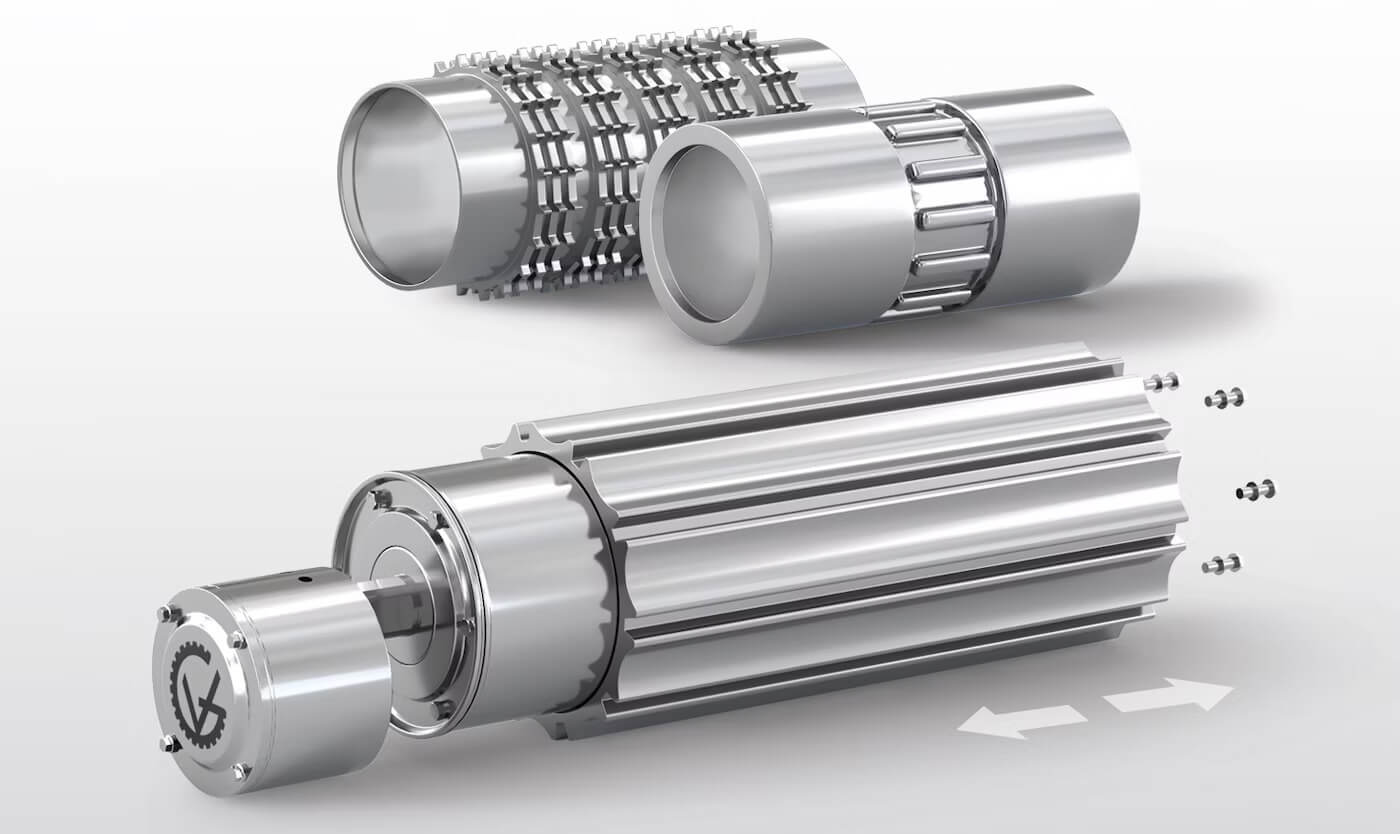

The new patented hygienic SSV-XP Drum Motor from VDG (Van der Graaf), making its PACK EXPO International debut, is designed with an exchangeable profiled sleeve that enables different belt profiles to be used without changing the drum motor. The profiled sleeve slides off the drum motor and is easily removed and replaced with another profiled sleeve to match the modular belt required on the conveyor. With the SSV-XP design, if the belt on the conveyor is required to be changed to a different belt profile, then only the sleeve needs to be changed over and not the entire drum motor.

“From a design perspective, the main point is sanitation,” Alex Kanaris of Van der Graaf told Packaging World at the show. “The traditional way of driving conveyor belts [sprockets on a square drive shaft] is not sanitary. A traditional belt drive has many crevices and spaces that trap food by-products and harbor bacteria, and it takes twice as long to clean using a significant amount of water. The drum motor with the continuous profile sleeve eliminates these harborage areas and is faster and easier to clean, saving time and water.” The hygienic SSV-XP Drum Motor is available in a range of diameter sizes, belt speeds, horsepower, and profiled sleeves for a variety of conveyor belt manufacturers to suit various belt conveyor applications.

The SSV-XP has a slide-on/slide-off continuous profiled sleeve over the drum motor that attaches simply with six screws, provides the flexibility to adapt various types of conveyor belts without removing the drum motor, and exceeds sanitary standards.

View original article