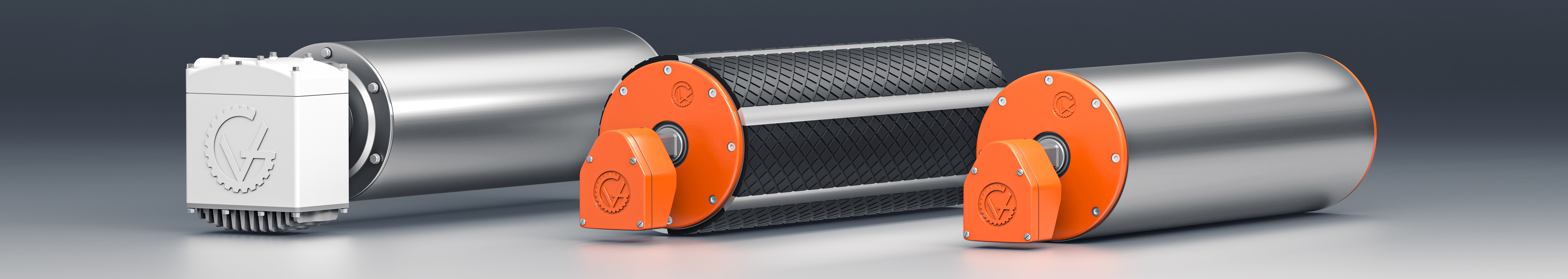

The Standard Series Drum Motor is designed for belt conveyors for a variety of material handling and processing applications, including packaging, warehousing, postal, parcel, automotive, and baggage handling.

All drive components are enclosed and protected inside the drive roller and are designed for 80,000 hours of continuous operation before maintenance, reducing operating costs while increasing throughput. With no external components, VDG Drum Motors eliminate the safety risks associated with traditional external motor and gearbox conveyor drives. The low-profile drum motor reduces the overall footprint of the conveyor, allowing more conveyor lines to fit on the same floor or overhead space.

The electric motor is in-line with the gear reducer and operates at 96% mechanical efficiency, reducing energy consumption and costs. Gears are manufactured in-house by VDG using state-of-the-art gear cutting and shaping equipment, honed and ground to DIN6 industry standards for low decibel noise levels that exceed OSHA requirements. Standard Series Drum Motors are available in a range of diameter sizes, belt speeds, horsepower, and with lagging options to suit various belt conveyor applications.

DESIGN BENEFITS

Space-saving design

Low decibel noise levels

Motor indexing up to 60 start/stops per minute

All enclosed one-component conveyor drive

Premium-efficiency electric motor

Maintenance-free for 80,000 hrs. of continuous operation

Configure your drive

| Diameter (inches) |

HP Range |

Drum Motor Series |

Dimensions |

Specifications |

Cross Sectional & Parts |

| 4.0 |

0.11 - 0.25 |

TM100B25 |

|

|

|

| 4.5 |

0.16 - 0.5 |

TM113B25 |

|

|

|

| 5.0 |

0.25 - 1.5 |

TM127B30 |

|

|

|

| 5.0 |

0.25 - 1.5 |

TM138B30 |

|

|

|

| 6.5 |

0.75 - 3.0 |

TM160B40 |

|

|

|

| 8.5 |

2.0 - 7.5 |

TM215B40 |

|

|

|

| 8.5 |

2.0 - 7.5 |

TM215B50 |

|

|

|

| 12.5 |

5.0 - 15.0 |

TM315B50 |

|

|

|

| 12.5 |

5.0 - 15.0 |

TM315B60 |

|

|

|

| 12.5 |

10.0 - 15.0 |

TM315A75 |

|

|

|

| |

Standard |

Option |

| Power connection |

Junction box |

Cable |

| Electric motor |

Class H

Inverter Duty

VFD Rated

VPi |

GV Thermal Overload Protection |

| Voltage |

480V

3 phase, 60Hz |

220V, 240V, 600V |

| Backstop |

|

CW

CCW |

| Electromagnetic Brake |

|

Available for TM127 and higher |

| Lagging |

|

VDG patented IronGrip™ Lagging (TM160 and higher), Black Rubber, USDA/FDA Blue or White Nitrile Rubber: Plain, Diamond, or Chevron |

Configure your drive