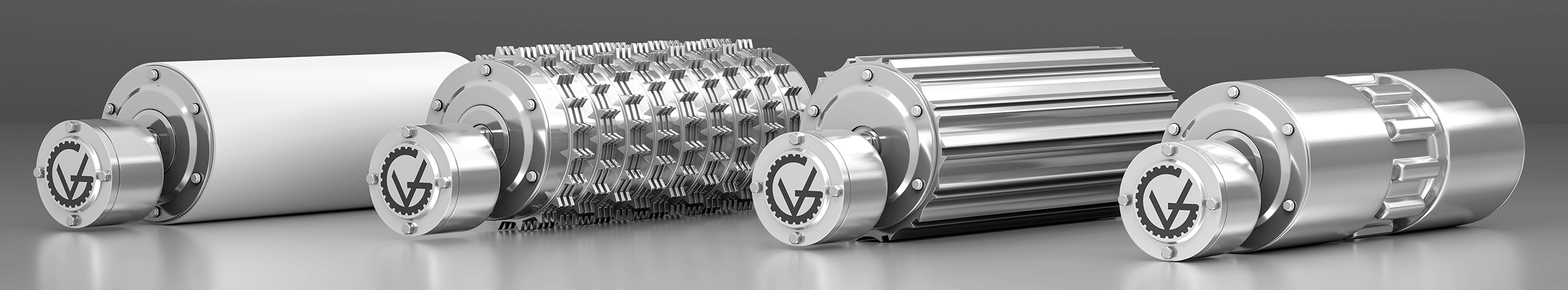

The SSV Series Drum Motor is the most hygienic conveyor belt drive designed and engineered for food, beverage, and pharmaceutical conveyor applications where sanitation and food safety are paramount.

The SSV Drum Motor is constructed of 316-stainless steel. It is USDA-approved, features an IP69K-rated sealing system, withstands pressure washdown up to 3,000 psi and exceeds the highest level of sanitation requirements. For modular, wire mesh, and monolithic thermoplastic conveyor belts, SSV Drum Motors have the belt profile machined directly on the drive drum or on an exchangeable profiled sleeve (SSV-XP) to drive the belt without using sprockets. Belt profiles are available for various belt manufacturers including Intralox, Wire Belt, Habasit, Gates, Cambridge and Volta.

SSV Series Drum Motors are available in a range of diameter sizes, belt speeds, horsepower, and with FDA/USDA-approved lagging and belt profile options to suit various belt conveyor applications.

DESIGN BENEFITS

316-stainless steel construction

IP69K-rated sealing system

Withstands pressure washdown up to 3,000 psi

Drives modular and monolithic belts without sprockets

All enclosed one-component conveyor drive

Premium-efficiency electric motor

Maintenance-free for 80,000 hrs. of continuous operation

Space-saving design

Configure your drive

| Diameter (inches) |

HP Range |

Drum Motor Series |

Dimensions |

Specifications |

| 4.0 |

0.11 - 0.25 |

TM100B25 |

|

|

| 4.5 |

0.16 - 0.75 |

TM113B25 |

|

|

| 5.0 |

0.25 - 1.5 |

TM127B30 |

|

|

| 5.4 |

0.25 - 1.5 |

TM138B30 |

|

|

| 6.5 |

0.75 - 3.0 |

TM160B40 |

|

|

| 8.5 |

2.0 - 7.5 |

TM215B40 |

|

|

| 8.5 |

2.0 - 7.5 |

TM215B50 |

|

|

| |

Standard |

Option |

| Power Connection |

Junction Box |

Cable |

| Electric Motor |

Class H

Inverter Duty

VFD Rated

VPi |

GV Thermal Overload Protection |

| Voltage |

480V

3 phase, 60Hz |

220V, 240V, 600V |

| Backstop |

|

CW

CCW |

| Electromagnetic Brake |

|

Available for TM127 and higher |

| Lagging |

|

USDA/FDA Food Grade Blue or White Nitrile Rubber: Plain, Diamond or Chevron |

| Drum Profile |

|

Belt profiles for various belt manufacturers

Profiled Sleeve (XP) for various belt manufacturers |

Configure your drive